Energy-Efficient Solutions: Best Options for Pharmaceutical Freezers

Energy-efficient solutions are an ongoing necessity in modern healthcare facilities. On the other side, medical refrigerators are energy hogs while being essential parts of hospitals. Finding out how much power medical refrigerators use and what strategies work to reduce that power consumption is crucial.

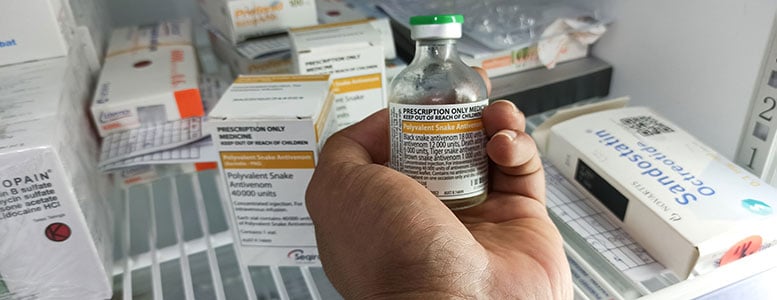

Many different types of healthcare institutions, including hospitals, clinics, and labs, make use of medical freezers. When it comes to storing specimens and medical supplies, these devices are indispensable. Nevertheless, medical refrigerators have a high energy consumption rate, making energy savings a valuable commodity.

In the fast-evolving landscape of pharmaceuticals, ensuring the integrity of sensitive materials is paramount. Pharmaceutical freezers play a crucial role in maintaining the efficacy of vaccines, drugs, and other temperature-sensitive products. However, with the rising focus on sustainability, it's essential to explore energy-efficient solutions without sacrificing performance. Let's delve into the world of pharmaceutical freezers and discover the best eco-friendly options that prioritize both efficiency and environmental responsibility.

Understanding Energy-Efficient Technology in Pharmaceutical Freezers

Pharmaceutical freezers have come a long way from being mere storage units. The laboratory is among the most energy-intensive buildings in many nations. Refrigerators, freezers, incubators, centrifuges, and computers used to analyze research data represent a significant portion of energy use. Pharmacists' refrigerators are notoriously known to use four to five times as much electricity as average appliances. The latest technological advancements focus on energy efficiency, aiming to reduce environmental impact while cutting operational costs. From innovative insulation materials to smart temperature control systems, understanding the intricacies of these technologies is key.

Numerous companies provide pharmaceutical refrigerators that are energy efficient, so you really do have a lot of options. Here are some things to think about before buying a new or upgraded pharmaceutical refrigerator if you want to reduce your energy use and environmental impact.

Type of Compressor: A compressor accounts for about 75% of an electric refrigerator's power consumption, making it an essential component. While inverter compressors may work at varying speeds, non-inverter compressors will cycle on and off at a constant speed. Therefore, an inverter compressor allows a pharmaceutical refrigerator to operate at low speeds while using the least amount of energy necessary to achieve the optimal degree of refrigeration.

Refrigerant Type: Even though it's crucial for refrigerators to have refrigerant, most consumers don't give it much thought when buying a refrigerator. In conjunction with the compressor and evaporator fan, it draws heat from the surrounding air and turns it into cold air. Companies like ECOFRIJ are slowly switching over their refrigerator models to utilize R600a, a refrigerant that is both more energy efficient and has a lower environmental effect than R-134a.

Interior Lighting Type: Some pharmaceutical refrigerator brands sold in Malaysia, including REMI, still use fluorescent lights. The fact that fluorescent lights produce more heat than light is probably previously known to you. After only ten seconds of opening the refrigerator door, the light bulb will be too hot to touch. Think about how much more effort your refrigerator needs to put in every time that occurs so it can cool the lightbulb down again.

Instead, light-emitting diode bulbs are far more energy efficient and produce significantly less heat than fluorescent lights. LEDs, or light-emitting diodes, are a more modern technological substitute for incandescent light bulbs.

Regulatory Compliance and Energy-Efficiency Standards for Freezers

The pharmaceutical industry operates within stringent regulatory frameworks. Manufacturers and facilities must align their operations with energy-efficiency standards. We'll explore how compliance with these regulations not only ensures legality but also contributes to the industry's overall commitment to sustainable practices.

Regulatory Compliance: Navigating the Regulatory Tapestry

Environmental Regulations: Regulatory bodies worldwide are tightening the reins on industries that utilize refrigeration technology. Stricter controls on the use of certain refrigerants, such as hydrofluorocarbons (HFCs), are aimed at curbing their environmental impact. Companies must stay abreast of evolving regulations, ensuring their freezers align with current and forthcoming standards.

Pharmaceutical Storage Guidelines: For pharmaceutical companies, adherence to regulatory standards, such as those laid out by agencies like the U.S. Food and Drug Administration (FDA) or the European Medicines Agency (EMA), is non-negotiable. Compliance encompasses temperature control, monitoring, and documentation to safeguard the integrity of stored medications.

Energy Efficiency and Eco-design Directives: Governments and international organizations are increasingly promoting energy efficiency through directives and standards. Ecodesign directives, for instance, set benchmarks for the energy performance of products, including freezers. Compliance not only reduces environmental impact but also often translates into cost savings for businesses.

Energy-Efficiency Standards: Paving the Way for Sustainability

ENERGY STAR Certification: Freezers that meet the stringent energy efficiency criteria set by ENERGY STAR receive certification. This voluntary program, widely recognized globally, empowers consumers and businesses to make informed choices, driving the market towards more sustainable products.

ENERGY STAR Certification: Freezers that meet the stringent energy efficiency criteria set by ENERGY STAR receive certification. This voluntary program, widely recognized globally, empowers consumers and businesses to make informed choices, driving the market towards more sustainable products.

LEED Certification: For organizations committed to green building practices, Leadership in Energy and Environmental Design (LEED) certification is a valuable accolade. Energy-efficient freezers contribute towards achieving LEED points, promoting overall sustainability in construction and operation.

Innovations in Design: Manufacturers are responding to the call for energy-efficient solutions by integrating advanced technologies into freezer design. Features like smart temperature controls, improved insulation materials, and variable-speed compressors enhance energy performance, reducing both operational costs and environmental impact.

Comparing Traditional vs. Eco-Friendly Pharmaceutical Freezers

Traditional freezers have been the backbone of pharmaceutical storage for decades. However, eco-friendly alternatives are gaining momentum. We'll weigh the pros and cons of traditional versus environmentally conscious options, helping you make informed decisions that align with your organization's values and goals. Traditional pharmaceutical freezers have long been the workhorses of cold storage in the medical field. These freezers typically rely on conventional refrigerants like hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs). While efficient in maintaining low temperatures necessary for preserving pharmaceuticals, their environmental footprint raises concerns. The release of these refrigerants into the atmosphere contributes to ozone depletion and global warming, aligning traditional freezers with a less sustainable trajectory.

In response to the ecological challenges posed by traditional freezers, eco-friendly alternatives have emerged as beacons of change. These freezers leverage advanced technologies and environmentally conscious refrigerants, such as hydrofluoroolefins (HFOs) and natural refrigerants like propane and isobutane. The transition to eco-friendly freezers signifies a commitment to sustainability, offering pharmaceutical companies an opportunity to align their operations with global environmental goals. Moreover, these freezers often come equipped with energy-efficient features, contributing to a reduction in overall energy consumption.

Environmental Impact: Traditional freezers bear the brunt of criticism for their contribution to ozone depletion and global warming. In contrast, eco-friendly freezers, with their use of low-impact refrigerants, present a more sustainable choice in line with contemporary environmental standards.

Energy Efficiency: Eco-friendly freezers often incorporate innovative designs and features aimed at reducing energy consumption. This not only translates to cost savings but also aligns with broader corporate social responsibility initiatives.

Regulatory Compliance: As environmental regulations become more stringent, pharmaceutical companies must consider the evolving landscape of compliance. Eco-friendly freezers position organizations favorably in meeting current and future regulatory requirements.

Temperature Precision: Both traditional and eco-friendly freezers excel in maintaining precise temperature conditions crucial for preserving pharmaceutical integrity. However, advancements in eco-friendly freezer technologies have narrowed the performance gap, making them increasingly competitive.

Optimizing Performance: Efficiency Metrics in Pharmaceutical Freezers

In the intricate world of pharmaceutical storage, optimizing performance is not just a goal but a critical necessity. As the pharmaceutical industry continually evolves, the focus on efficiency metrics in pharmaceutical freezers takes center stage. This discussion explores the key metrics that define efficiency in these essential storage units, shedding light on how advancements in technology are revolutionizing the preservation of vital medications.

Temperature Uniformity: Ensuring uniform temperature distribution within a freezer is paramount. Fluctuations can compromise the efficacy of stored medications. Modern freezers employ advanced airflow systems and temperature controls to maintain consistency throughout the storage space.

Setpoint Precision: The ability to set and maintain precise temperatures is a hallmark of an efficient pharmaceutical freezer. Narrow temperature bands, often measured in tenths of a degree, are critical for preserving the integrity of sensitive pharmaceuticals.

Energy Consumption: With sustainability at the forefront, minimizing energy consumption is imperative. Energy-efficient freezers leverage technologies like variable-speed compressors, LED lighting, and advanced insulation materials to reduce the environmental footprint and operational costs.

Storage Density: Efficient use of space is critical in pharmaceutical storage. Freezers designed with optimized shelving configurations and adjustable storage options maximize the storage density, allowing for the accommodation of a larger quantity of medications within a compact footprint.

Inventory Management Systems: Integration with sophisticated inventory management systems streamlines the tracking and retrieval of pharmaceuticals. This not only enhances operational efficiency but also minimizes the risk of errors in medication handling.

Reliability Metrics: A reliable freezer operates consistently with minimal downtime. Metrics such as mean time between failures (MTBF) and mean time to repair (MTTR) provide insights into the reliability of a freezer, helping businesses make informed decisions about equipment selection.

Predictive Maintenance: Leveraging technology for predictive maintenance reduces the risk of unexpected breakdowns. Monitoring systems that analyze data on temperature fluctuations, compressor cycles, and other variables enable preemptive maintenance, ensuring continuous and reliable operation.

Ensure Your Pharmaceutical Freezer Keeps Operating During a Power Outage

No matter how advanced a freezer is, power outages can pose a significant threat to pharmaceutical storage. In this product tie-in section, we'll explore solutions that guarantee uninterrupted operation during power disruptions. Discover how Medi-Products' cutting-edge technology ensures your pharmaceutical freezer remains reliable, even in challenging circumstances.

No matter how advanced a freezer is, power outages can pose a significant threat to pharmaceutical storage. In this product tie-in section, we'll explore solutions that guarantee uninterrupted operation during power disruptions. Discover how Medi-Products' cutting-edge technology ensures your pharmaceutical freezer remains reliable, even in challenging circumstances.

Explore the world of eco-friendly options for pharmaceutical freezers with us. Sustainability doesn't have to come at the cost of efficiency. Learn from the experts at Medi-Products, where innovation meets responsibility. Stay ahead in the pharmaceutical game by embracing the future of energy-efficient freezer solutions!