How to Troubleshoot Temperature Excursions?

Download our free temperature excursions poster below detailing everything from this blog including:

- Warning signs of a temperature excursion

- Actions items to take during an excursion event

- Preventative measures you can take

As a primer, we’ve detailed below everything you need to know about temperature excursions so you can be prepared if one happens inside your healthcare facility.

What Is a Temperature Excursion?

In the United States, the CDC defines a temperature excursion as "any break in the cold chain of a pharmaceutical product". The "cold chain", is a series of refrigerated production, storage and distribution activities. These processes ensure that vaccines and other pharmaceuticals remain at the correct temperature. Maintaining proper temperatures and avoiding excursions ensures that materials remain safe and effective.

Meanwhile, according to the European Compliance Academy, a temperature excursion is defined as: "a deviation from the labeled storage condition of a product for any duration".

This includes excursions during transportation or distribution.

When exposed to temperatures beyond their limits, pharmaceuticals quickly begin to break down. Even if the excursion  lasts only a short amount of time.

lasts only a short amount of time.

As a result of this degradation, there will be a generation of impurities in the product. Degradation products like this are not wanted in the manufacturing chain. Additionally, they present a threat to patients' health.

As such, the raw materials needed to produce pharmaceuticals need to be maintained as well. Active pharmaceutical ingredients (API) need proper temperatures during the manufacturing process. If not properly handled, they can lose potency, effectiveness and safety before they're even distributed.

Deviating from optimal storage conditions can result in significant changes in the API. This includes degradation, decay, polymerization, and an increase in impurity levels.

Reasons Why Temperature Excursions Occur

Air handling units (AHU) maintain the required temperature in pharmaceutical factories. So, the design and capacity of these units reflect the API manufacturers temperature requirements during the production process. Regardless, temperature excursions are unavoidable. Even in the manufacturing area and during transportation.

In the manufacturing area, temperature excursions happen for several reasons, including:

- An insufficient number of air handling units to maintain the desired temperature conditions

- A leaked or ruptured air duct

- Mechanical failure in air handling units

- Unprecedented temperature fluctuations.

- Power outages interrupting the AHU's operation

- Poor adherence to good manufacturing practices (GMP) on the production floor

- Poor staff oversight of temperatures/ Poor Quality Control

- Extreme weather conditions and poor or absent SOPs for handling them

Effects Of Temperature Excursion

A temperature excursion affects product quality in two potential ways. But, the impacts of high temperatures are different than those of temperatures that are too low. Though the result is the same nonetheless - a compromised product.

Products sensitive to high temperatures experience degradation that can cause a decrease in the active ingredient content of the product.

This happens due transformations in the affected, degraded components within. The transformation could be oxidative, hydrolytic, or some other form. As a result, much more toxic variants of the compound begin to appear. The amount of degradation/toxicity is dependent on length and severity of the temperature excursion, which can result in:

- Components becoming discolored.

- Changes in dissolution rates

- Separation of emulsions

Products sensitive to a low temperature usually get damaged by phase changes caused by the freezing process. As a result, the physical atomic structures of the chemicals experience permanent changes.

Products with large quantities of water, like creams or biologicals, are especially prone. Often, they'll lose their properties after experiencing excessive freeze-thaw or temperature cycles. Because water can easily change temperature, the presence of ice quickly damages product.

How To Measure Temperature Excursions

One responsibility of pharmaceutical manufacturers is guaranteeing every batch is a safe and effective high quality product. One of the ways to make this happen is through continuous temperature monitoring. By monitoring the temperature range, they can catch any excursions that occur. After which, they can take the necessary steps to address them immediately.

The Center for Disease Control recommends using a continuous temperature monitoring device (TMD) to track excursions. The recommended TMD is a digital data logger (DDL) that has the following characteristics:

- Ability to record the logged temperature values to a computer system for review.

- The digital data logger's calibration status must be regularly verified, with up-to-date software. This ensures accurate information about storage conditions.

The following information is required when documenting temperature excursions:

- The date and time the temperature excursion occurred

- An inventory of affected products

- The storage unit air temperatures. Including the minimum and maximum temperatures observed during the temperature excursion, if available

- Ambient temperature (also referred to as “room temperature”).

- A general description of the event, such as the length of the temperature event. The digital data logger should provide this data.

- A list of any other items in the storage unit

- Documentation of any problems with the storage unit

All the data should be compiled, and a copy given to the distributor and recipient of the affected product(s).

How To Avoid and Combat Temperature Excursions

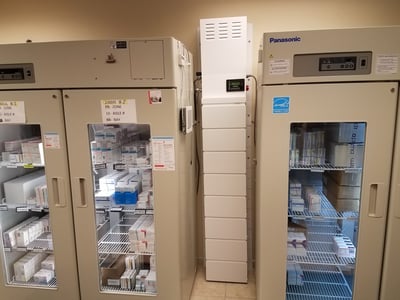

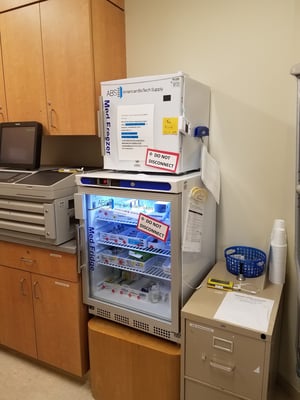

Simply put, any temperature excursion is a result of prolonged exposure to air that is room temperature or above. For end users of pharmaceuticals, the most likely scenario for them to experience a temperature excursion is because they’ve left the door open to a medical refrigerator/medical freezer or it has stopped running.

If Your refrigerator/freezer temperature has dropped below 35°F (2.0°C) for 15 or more minutes consecutively:

- Check the Placement of the Thermometer probe – Place in the middle and monitor temperature in 30-minute intervals

- Adjust Refrigerator/Freezer Temperature- Change temperature of appliance, if possible, to a warmer setting. Monitor and record = temperature every 30 minutes for next 2 hours.

- If temperatures remain out of range — implement facilities’ relocation plan. Immediately call vaccine manufacturer/distributor.

If your Refrigerator has risen above 46°F (7.7°C) or Freezer has risen above 5°F(-15°C) for 60 minutes or more consecutively:

- Check your power supply — if your area is experiencing a power outage estimated to last 2 or more hours and your facility does NOT have a dedicated backup power source for your cold storage appliances, implement emergency relocation plan

- Check the door to the storage unit — ensure nothing is preventing door from securely closing. If so, adjust accordingly and shut door completely.

- Adjust the refrigerator/freezer temperature — Change temperature of appliance to a cooler temperature is possible. Monitor and record temperature every 30 minutes for next 2 hours.

- If temperatures remain out of range— implement facilities’ relocation plan. Immediately call vaccine manufacturer/distributor.

In short, unless total failure of the appliance has occurred, the most common solutions to these problems are:

- A door alarm to ensure staff always close it

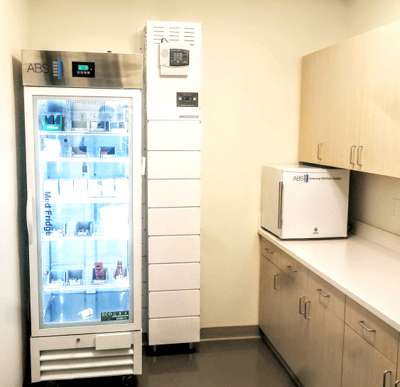

- A backup power solution to ensure any medical and pharmaceutical refrigerators continue to operate as normal.

While door alarms are fairly easy to source tools, a reliable and powerful backup power system for refrigerators can be harder to find.

Luckily, battery backup systems offer instant and automatic power for medical appliances as soon as the power goes out. As a result, no staff needs to be on-site to keep track of or start the generator and vaccines will continue to remain safe—with no extra work required.

Additionally, their vertical, cabinet-like design and leak-proof batteries mean they can be installed in even the tightest spaces and oriented in anyway to make them fit. Plus, if your medication or vaccine room is truly tight on space, a hardwired backup power unit can instantly supply remote power to your appliance—directly via the outlet its already plugged into.

Regardless of what kind of system is the best fit, they ensure that your entire stock of vaccines are protected from a sudden loss of power (and the resulting temperature excursions) by guaranteeing a seamless transition from utility power to backup power.

Even better, is that battery generators can be outfitted with as much power as you want. So system’s can be designed with enough power to protect a facility’s inventory:

- Overnight

- All day

- Over a weekend

- Or even for a whole week.

So, to protect your facility from tens of thousands of dollars in lost vaccine stock, speak to a Medi-Products battery backup expert.

They’ll help design you a system that both meets your power needs and will fit inside your facility—for a much lower cost than what your vaccines are worth. So a backup power system pays for itself the first time your power goes out.

Designing a system for you is as easy as taking a picture of your appliance’s nameplate, and a photo of the room where it’s in.

Then, you just email both photos to our Product experts, and we’ll provide you with multiple options for backup power protection.

For more information contact: